USA Welding Supply

Welding Wire / Filler Metal - .045 Diameter - AFM-81T1-B2 .045 X 33 - 33-lb Spools

Welding Wire / Filler Metal - .045 Diameter - AFM-81T1-B2 .045 X 33 - 33-lb Spools

Regular price

$1,754.50 USD

Regular price

Sale price

$1,754.50 USD

Unit price

per

Tax included.

Shipping calculated at checkout.

Couldn't load pickup availability

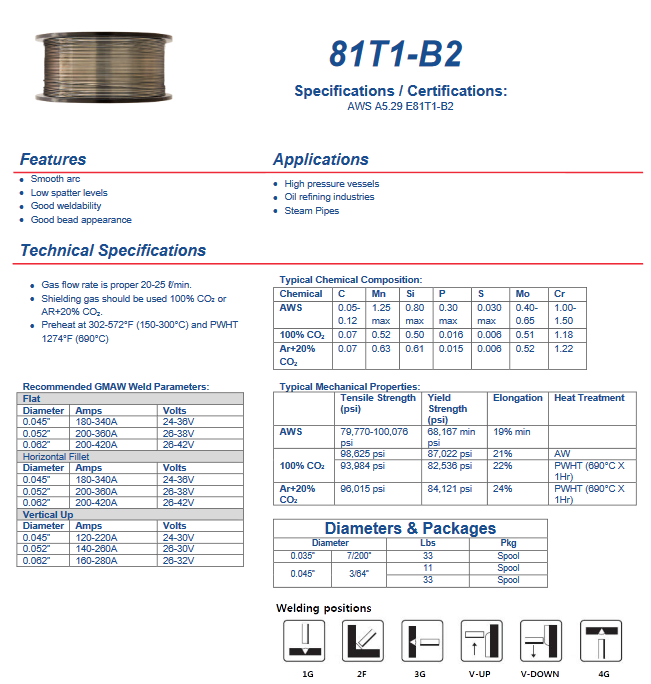

- A titania slag formulation flux cored wire for single or multi-pass welds on 1.25% Cr 0.5% Mo steels

- The weld deposits are designed to operate at high temperature service. The shield gas recommended is 100% CO2.

- A preheat of 200-350°C and a post-weld heat treatment of 680-730°C for 1 hour per inch of thickness followed by air cooling to ambient temperature is required.

- For use with high pressure vessels, oil refining industries, steam pipes of boilers

- This wire is designed for welding of 1.25% Cr-0.5% Mo steel used for high pressure vessels, oil refining industries, steam pipes of boilers etc.

- It is a rutile type flux cored wire for all position welding.

- It provides smooth arc, low spatter levels, good weldability, and good bead appearance.

- The weld metal contains about 1.25% Cr. 0.5% Mo, so it has good crack and heat resistance.

This Welding Wire / Filler Metal is designed for the welding of 1.25% Cr-0.5% Mo steel. It provides an ideal solution for high pressure vessels, oil refining industries, and steam pipes of boilers, with a titania slag formulation flux cored wire for single or multi-pass welds. Preheat of 200-350°C and post-weld heat treatment of 680-730°C for 1 hour per inch of thickness are required. Experienced welders will appreciate its easy arc start, smooth arc, low spatter levels and good weldability.